-

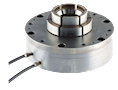

MBS Diaphragm Chuck Models

mbs-diaphragm-chuck-models

-

MBS/L Air Operated Diaphragm Chucks

Design

Self-contained design with built-in air cylinder. Air is supplied to the chuck by a multi passage air tube assembly with a rotary coupling. Coolant through the spindle capability is standard.

Application

OD and ID chucking for cylindrical grinding, turning, and hard turning. Ideal for workpieces requiring high concentricity, and/or close round ness. Ideal for fragile parts which are easily distorted, and applications requiring high spindle speeds. -

MBS/Z Draw Bar Operated Diaphragm Chucks

Design

Draw tube operated design. Can be actuated with either a hydraulic or pneumatic cylinder mounted at the rear of the machine spindle.

Application

OD and ID chucking for cylindrical grinding, turning, and hard turning. Ideal for workpieces requiring high concentricity, and applications requiring high chucking force and/or high spindle speeds. -

MBS/N Stationary Diaphragm Chucks

Design

Self-contained design with built-in air cylinder. Air ports are located on the side of the chuck body for stationary use.

Application

OD and ID chucking for milling, drilling, inspection, or any other non- rotating application requiring high concentricity and/or close workpiece roundness. The inherent spring characteristic of the diaphragm allows workpieces to be clamped without continuous air supply for pallet and tombstone applications.