Stationary air chucks are ideal for milling, drilling, tapping, and other applications requiring a compact self-contained workholding fixture. Air is supplied directly into the side of the chuck body, and the chuck can be mounted directly to the machine table or pallet. Through holes are available on all models.

Chuck Accuracy

- .00005" (0.0012mm) TIR is standard

- .00002" (0.0005mm) TIR is available

Chuck Size |

N/A 3 in80 mm |

| No. of Jaws1 | N/A 3 |

| Chuck Accuracy2 | N/A .00005 in.0012 mm |

| Jaw Stroke3 | N/A .050 in1.3 mm |

Max. Air Pressure |

N/A 100 psi0.7 MPa |

Through Hole |

N/A .475 in12 mm |

Chuck Weight |

N/A 3.0 lb1.4 kg |

Item No. |

N/A 01 030 315 |

Max. Clamp Force |

N/A 920 lbs4.1 kN |

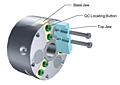

QC Quick Change Top Jaw System |

N/A

Patented jaw locating system reduces setup time by maintaining .0002" (0.005mm) TIR accuracy after jaw change, without remachining top jaws.

QC System Features

QC System Design  Loading zoom |

UP Ultra Precision Option |

N/A

Repeating accuracy to .000020" (0.0005mm) TIR  |

AL Automatic Lubrication Option |

N/A

Lubricate the chuck with an electric pump  |

|

N/A All Stationary Air Chucks include:

|

- 1 2 jaw configurations available for all air chuck sizes, 6 jaw configurations available on 10 inch (250 mm) models

- 2 Chuck accuracy is defined as the total indicator reading (maximum radial and lateral runout) of a master gage measured 1.0" (25 mm) from the face of a standard top jaw

- 3 Total jaw stroke (on diameter)